The INTEGRATE®-C, by HAPPE Spine, is the only orthopaedic medical device available on the market that capitalizes on the advantages of rod-like HA particles in the proprietary HAPPE® (HydroxyApatite Porous PolyEtheretherketone) biomaterial platform. The HA in HAPPE is firmly embedded in the PEEK matrix and exposed on all surfaces, including both machined surfaces and internal pore surfaces, due to the rod-like shape.

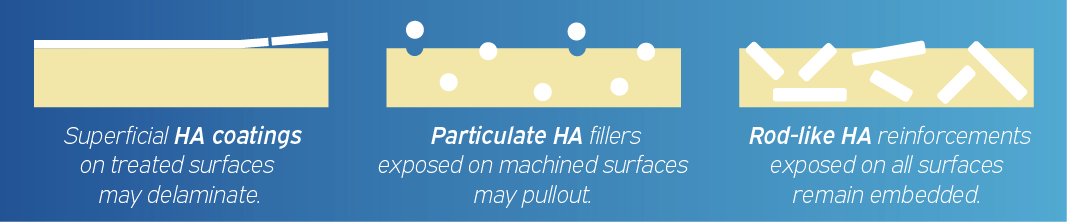

A white paper by Himed, an industry leader in hydroxyapatite (HA) biomaterials for 30 years, explains the underlying science, as well as advantages and disadvantages for various techniques used to modify PEEK with HA [1], including:

-

- superficial HA surface coatings

- PEEK composites impregnated with HA powders

- PEEK composites reinforced with rod-like HA whiskers

The Himed paper states that rod-like HA whiskers offer “materials with new and robust mechanical properties” and improve particle retention in surfaces for “properties that promote bone bonding,” [1]. Published studies have demonstrated that polymers, including PEEK, reinforced with rod-like HA whiskers exhibit significantly improved mechanical properties compared with spherical HA particles [2-4].

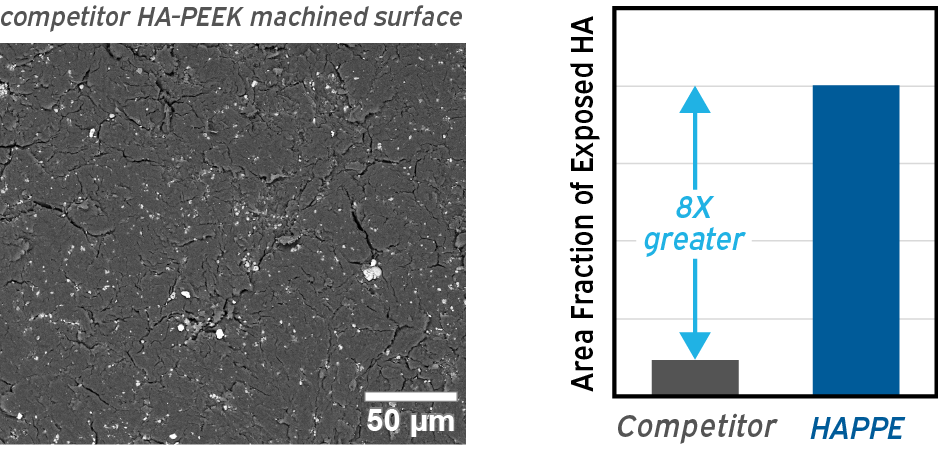

Furthermore, competitor HA impregnated PEEK products exhibit little HA exposure on machined surfaces, possibly because spherical HA particles are prone to pullout during machining [2]. The area fraction of exposed HA on machined surfaces of the HAPPE INTEGRATE®-C is ~8X greater, on average, compared to competitor implants, as measured in electron micrographs such as those here [5].

Finally, note that bone-forming osteoblasts are about 20-30 µm in size, or about one-half the length of the scale bar in the micrographs shown above for both HAPPE and competitor products. HAPPE surfaces are designed for happy osteoblasts.

[1] C. Rosenblum and E. Valliant, “Techniques to Enhance the Bioactivity of Polyetheretherketone (PEEK),” Himed, Old Bethpage, NY (2024). Weblink

[2] R.K. Roeder and T.L. Conrad, “Bioactive Polyaryletherketone Composites”; pp. 163-179 in the PEEK Biomaterials Handbook. Edited by S.M. Kurtz. Elsevier, Inc., Amsterdam, 2012. doi:10.1016/B978-1-4377-4463-7.10011-9

[3] R.K. Roeder, M.S. Sproul and C.H. Turner, “Hydroxyapatite whiskers provide improved mechanical properties in reinforced polymer composites,” J. Biomed. Mater. Res., 67A [3] 801-812 (2003). doi:10.1002/jbm.a.10140

[4] R.J. Kane, G.L. Converse and R.K. Roeder, “Effects of the reinforcement morphology on the fatigue properties of hydroxyapatite reinforced polymers,” J. Mech. Behav. Biomed. Mater., 1 [3] 261-268 (2008). doi:10.1016/j.jmbbm.2008.01.004

[5] Data on file, HAPPE Spine, LLC.